Industrial Waste Water Treatement Plants-Preventative Maintenance

The goal of preventative maintenance is to prevent the failure of pumps and equipment before it actually happens. Aimed at the prevention of breakdowns and failures, some tasks should occur weekly, monthly, quarterly or annually.

Preventative maintenance activities include lift stations, air release valves (ARV’s), headworks structures aeration equipment and return and waste sludge pumps and digestion aeration equipment. Partial or complete overhauls at regular specified periods; oil changes and lubrication.

Benefits of a good Maintenance Program

- Routine Inspections of equipment

- Periodic calibration and adjustments

- Development of a long-term overhaul or outage program

- Better utilization/scheduling of personnel

- Improved understanding and knowledge of the equipment

- Better organization of equipment maintenance procedures

- Efficient use of lubricants

- Efficient purchase of spare parts

- Better organization of maintenance department operations.

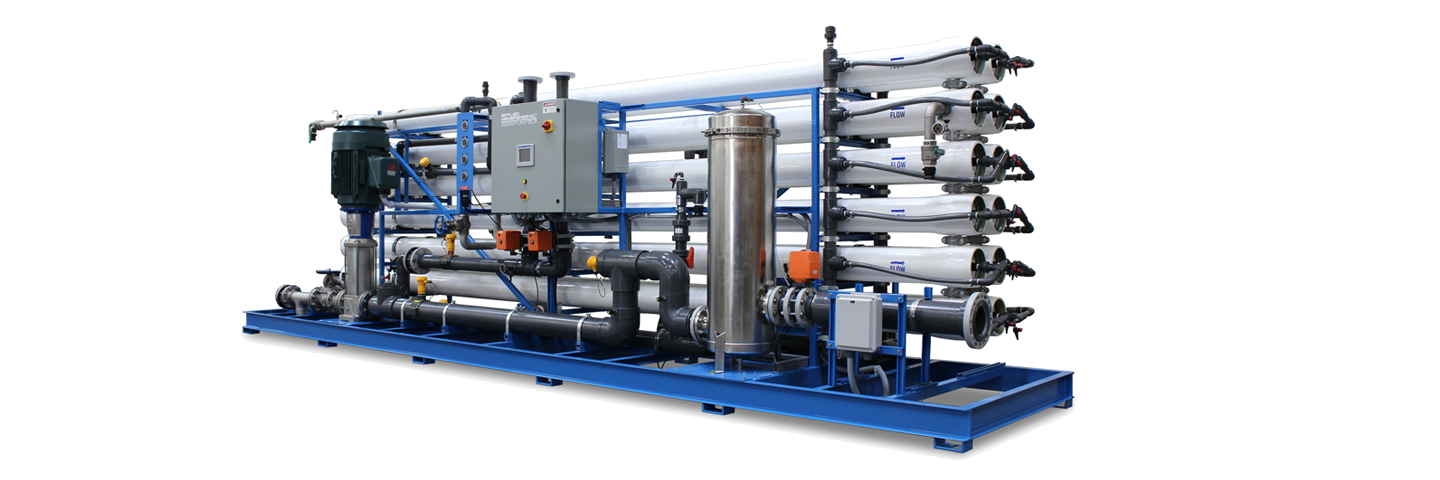

New Industrial Brackish Water Reverse Osmosis Supply and Installation

Reverse Osmosis (RO) systems are known for their ability to purify water and reduce 99% of contaminants. This RO series specializes in industrial grade systems for brackish, surface, and municipal water treatment. With upgraded industrial quality materials and high capacity technology, these industrial BWRO systems are engineered to purify elevated levels of water for almost every industry. Our systems are uniquely designed and engineered in the United States. Our industrial BWRO systems have been strategically designed to be energy efficient and environmentally friendly while producing some of the most high-quality water.